Science

Preventing Hydrogen-Induced Cold Cracking in Welding Processes

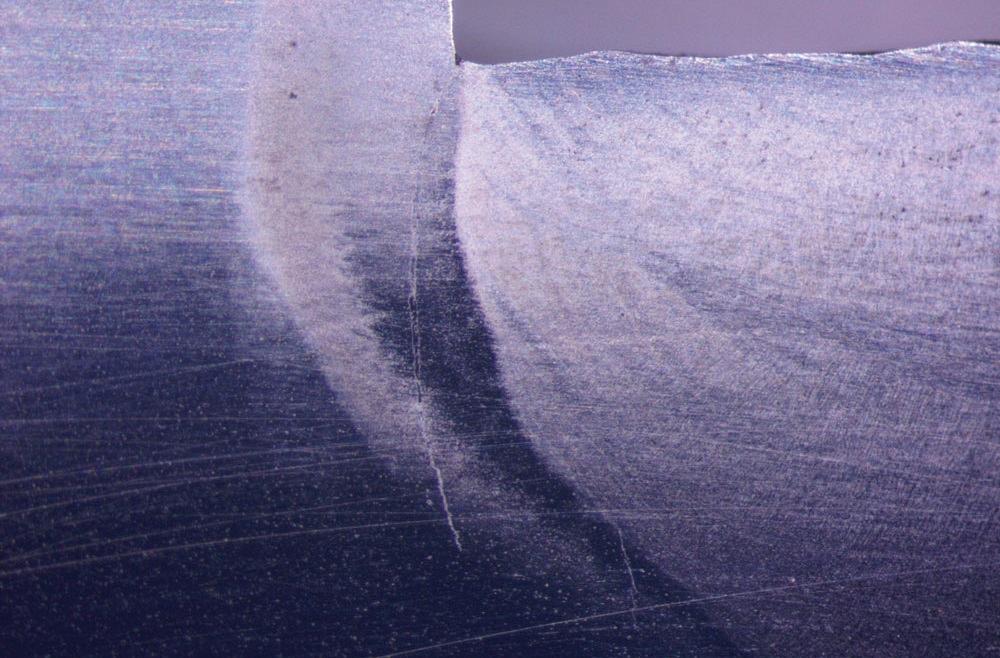

Hydrogen-induced cold cracking (HICC) poses significant risks in the welding industry by causing welds to crack after completion and cooling. This phenomenon requires three conditions: the presence of hydrogen, a hard and brittle microstructure, and tensile stresses. Eliminating any of these factors can prevent HICC, which is crucial given that prevention is typically more cost-effective than remediation.

Understanding Hydrogen Sources

Hydrogen can be introduced to weld metal through various avenues, including the welding process itself, environmental factors, and contaminants. The welding methods employed can significantly impact hydrogen levels in the weld. Processes such as Gas Tungsten Arc Welding (GTAW), Submerged Arc Welding (SAW), and Gas Metal Arc Welding (GMAW) can produce welds with low hydrogen content.

When these methods are impractical, Shielded Metal Arc Welding (SMAW) with low-hydrogen electrodes, specifically E7018-H4 or H8, can also achieve low hydrogen levels. Proper storage of these electrodes is vital for maintaining their performance. They must be kept in hermetically sealed packaging and stored in heated containers immediately upon opening. Electrodes exposed to the environment for more than four hours should be discarded or reconditioned to ensure safety.

Welding Techniques to Minimize HICC Risks

Preparation and cleanliness of the weld joint play a crucial role in preventing HICC. Contaminants such as grease, oil, paint, and rust can release hydrogen when subjected to the extreme heat of welding. Therefore, meticulous cleaning of the weld joint and surrounding areas is essential. Porous surfaces, like those created by plasma or oxyfuel cutting, can trap moisture and should be ground to expose clean metal.

Preheating the workpiece is an effective method to slow cooling rates and reduce hydrogen diffusion. Typical preheat temperatures range from 100 to 200 degrees Celsius, depending on material thickness and carbon equivalent. Thicker materials require higher preheat temperatures to achieve the desired cooling rate. After welding, practices such as using higher heat inputs and covering welds with insulation can further aid in hydrogen diffusion.

Post-weld heat treatment is beneficial in critical applications, as it relieves residual stresses and allows additional hydrogen to escape from the weld zone. This method is particularly important for piping and pressure vessels, where failure can have severe consequences.

Reducing stress in weldments requires careful planning. While welders may not directly control residual stresses, they can minimize them by eliminating gaps, avoiding overly constrained joints, distributing welding around the workpiece, and maintaining low interpass temperatures.

Inspection is another critical aspect of HICC prevention. Since cracks may not appear until after welding is complete and the weld has cooled, inspections should occur at least 48 hours after welding. Areas requiring close examination include weld toes, high restraint regions, and geometries that may create stress concentrations.

Implementing a systematic approach to prevent HICC can mitigate the high financial and reputational costs associated with welding failures. This approach should prioritize applications involving susceptible materials, high-strength materials, thicker sections, and highly restrained joints. Establishing qualified welding procedures and educating welders and supervisors on HICC dangers are essential steps.

Investing in suitable equipment, such as proper electrode storage ovens, preheating tools, and inspection devices, is far less expensive than addressing the ramifications of a single HICC-related failure. Ultimately, fostering attention to detail and promoting education about HICC within the workplace culture can lay the groundwork for achieving crack-free welds.

Jeff Molyneaux, executive director and CEO at the Materials Joining Innovation Centre (MaJIC), emphasizes the importance of these practices in creating safer welding environments. The centre, located at 140 Government Rd. E., Kirkland Lake, Ontario, serves as a resource for advancing welding technology and safety. For more information, contact MaJIC at 705-498-1567 or visit their website at www.majic-ca.org.

-

Science2 months ago

Science2 months agoToyoake City Proposes Daily Two-Hour Smartphone Use Limit

-

Health2 months ago

Health2 months agoB.C. Review Reveals Urgent Need for Rare-Disease Drug Reforms

-

Top Stories2 months ago

Top Stories2 months agoPedestrian Fatally Injured in Esquimalt Collision on August 14

-

Technology2 months ago

Technology2 months agoDark Adventure Game “Bye Sweet Carole” Set for October Release

-

World2 months ago

World2 months agoJimmy Lai’s Defense Challenges Charges Under National Security Law

-

Technology2 months ago

Technology2 months agoKonami Revives Iconic Metal Gear Solid Delta Ahead of Release

-

Technology2 months ago

Technology2 months agoSnapmaker U1 Color 3D Printer Redefines Speed and Sustainability

-

Technology2 months ago

Technology2 months agoAION Folding Knife: Redefining EDC Design with Premium Materials

-

Technology2 months ago

Technology2 months agoSolve Today’s Wordle Challenge: Hints and Answer for August 19

-

Business2 months ago

Business2 months agoGordon Murray Automotive Unveils S1 LM and Le Mans GTR at Monterey

-

Lifestyle2 months ago

Lifestyle2 months agoVictoria’s Pop-Up Shop Shines Light on B.C.’s Wolf Cull

-

Technology2 months ago

Technology2 months agoApple Expands Self-Service Repair Program to Canada