Science

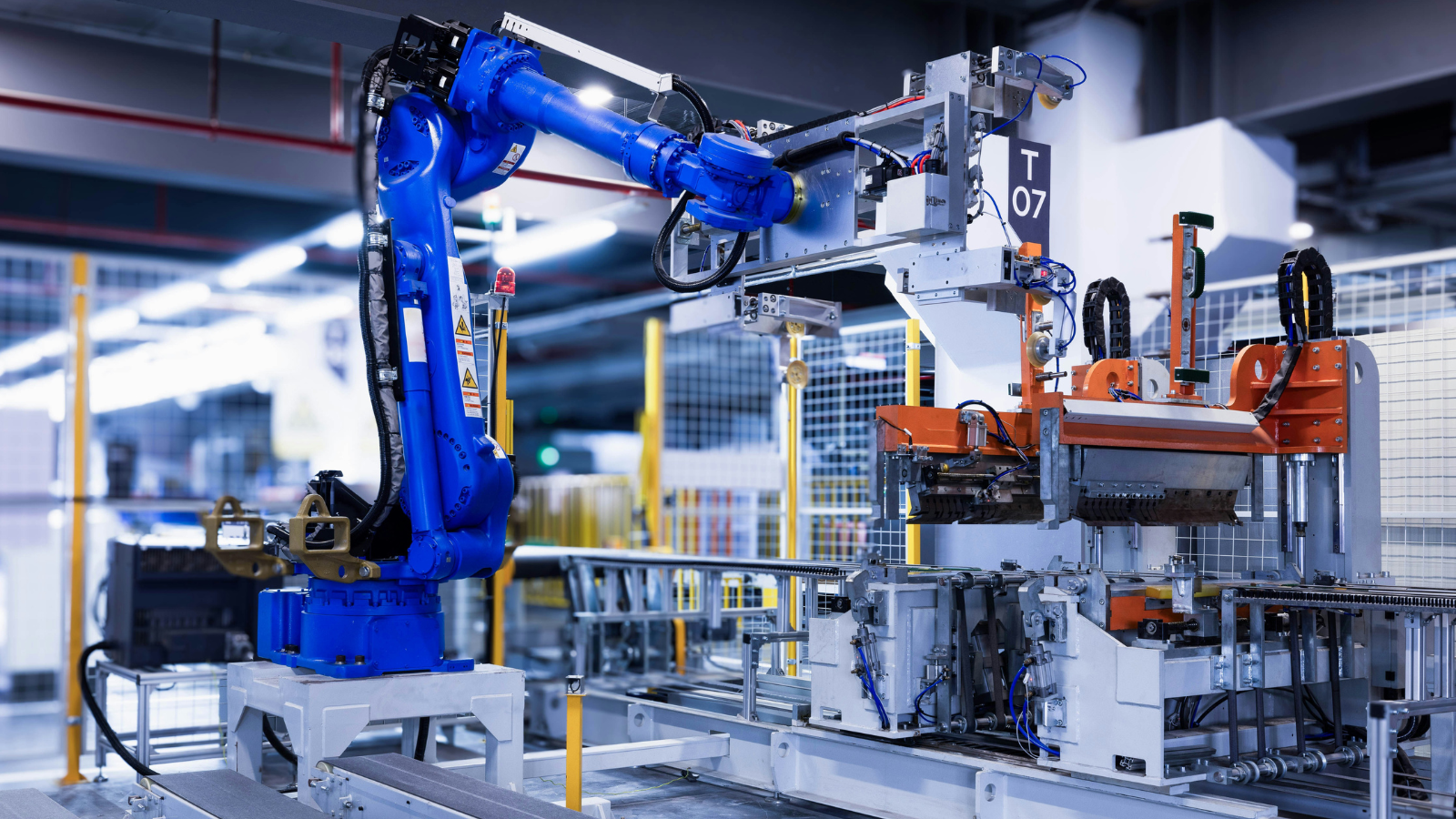

Smarter Machines Transform American Manufacturing Landscape

A significant shift is occurring in American manufacturing, particularly within the food and beverage sector, valued at approximately $1.1 trillion. Increasing inefficiencies and rising costs are pushing companies to seek innovative solutions. While products continue to flow, many production lines are reaching their operational limits, leading to heightened downtime and financial strain.

In recent years, the cost of system downtime has surged dramatically. Businesses previously faced losses of around $5,600 per minute; this figure has nearly doubled to $9,000 per minute. Such losses have serious implications for the industry, threatening its sustainability in a competitive market that demands speed and efficiency.

Engineering Innovations Address Industry Challenges

Amid these challenges, a new engineering mindset is emerging, spearheaded by leaders like Shubham Thakare, a senior mechanical engineer at a company specializing in modular automation. Over the past two years, Thakare’s projects have pushed the limits of modern filling and bottling systems, yielding substantial improvements for various clients.

One notable project involved addressing persistent issues faced by a major refrigerated dressing manufacturer. Inconsistent fill levels and lengthy changeover times were major bottlenecks caused by outdated equipment unable to handle varying viscosities. Thakare led the design of a new Monoblock filler system specifically tailored for viscous products. This innovative system employs adaptive servo-driven filling heads and FDA-compliant components, utilizing real-time feedback for calibration.

The outcomes were impressive: fill-level precision improved significantly, reconfiguration times decreased by 90%, and operational efficiency increased by 15%. The company expects to save approximately $1.2 million annually, not from a single overhaul, but through a series of targeted improvements that work synergistically.

Modular Solutions Redefine Production Capabilities

In a separate initiative, Thakare tackled a different challenge involving a legacy bottling manufacturer that needed to modernize to remain competitive. The aim was to develop a triblock system capable of filling, capping, and labeling bottles at over 150 units per minute while adhering to stringent safety and sustainability standards. Achieving this required a comprehensive rethinking of the entire system architecture.

Thakare and his team created a modular triblock platform that accommodates various bottle sizes and viscosities. The system incorporates machine vision for real-time defect detection and IoT-integrated quality control. Remarkably, this system was operational across multiple production lines within six months of deployment, achieving 99.9% accuracy and reducing material waste by 22%. The implementation of this setup has generated over $4 million in new annual revenue, positioning the company as a leader in this advanced technology segment.

The implications of these projects extend beyond individual client benefits. They indicate that American engineering remains at the forefront when focusing on modularity, scalability, and accessible design. These innovations challenge the notion that low-cost imports can dominate the market, highlighting that local manufacturing can excel in quality, flexibility, and sustainability.

Thakare’s modular philosophies are now shaping over 20% of new product designs within the company. His systems are being adapted for use across adjacent industries, and a new automation research team has been established to further expand these innovative platforms. Recognized for his contributions, Thakare received a fast-track promotion and now mentors new engineers, helping to set design standards that influence various departments.

As the manufacturing landscape increasingly embraces automation and reshoring, Thakare’s work exemplifies a problem-oriented approach to innovation. His focus is not solely on speed but also on creating environmentally friendly, intelligent, and reliable operations. By moving away from one-size-fits-all solutions, his adaptive systems are tailored to meet the specific needs of production lines, facilitating lasting change at an operational level.

This shift is paving the way for a future in American manufacturing that is not merely about survival but about leading the industry with innovative practices and sustainable solutions.

-

Science3 months ago

Science3 months agoToyoake City Proposes Daily Two-Hour Smartphone Use Limit

-

Top Stories3 months ago

Top Stories3 months agoPedestrian Fatally Injured in Esquimalt Collision on August 14

-

Health3 months ago

Health3 months agoB.C. Review Reveals Urgent Need for Rare-Disease Drug Reforms

-

Technology3 months ago

Technology3 months agoDark Adventure Game “Bye Sweet Carole” Set for October Release

-

World3 months ago

World3 months agoJimmy Lai’s Defense Challenges Charges Under National Security Law

-

Lifestyle3 months ago

Lifestyle3 months agoVictoria’s Pop-Up Shop Shines Light on B.C.’s Wolf Cull

-

Technology3 months ago

Technology3 months agoKonami Revives Iconic Metal Gear Solid Delta Ahead of Release

-

Technology3 months ago

Technology3 months agoApple Expands Self-Service Repair Program to Canada

-

Technology3 months ago

Technology3 months agoSnapmaker U1 Color 3D Printer Redefines Speed and Sustainability

-

Technology3 months ago

Technology3 months agoAION Folding Knife: Redefining EDC Design with Premium Materials

-

Business3 months ago

Business3 months agoGordon Murray Automotive Unveils S1 LM and Le Mans GTR at Monterey

-

Technology3 months ago

Technology3 months agoSolve Today’s Wordle Challenge: Hints and Answer for August 19